Industry Leaders Push for Clearer Standards on Concrete Wash Water Management

The British Concrete Transport Association (BCTA) brought together key industry stakeholders on 23 October 2025 for a dedicated Concrete Wash Water Working Group session, held at the Mudtech Tank Division facility. The meeting brought together specialists from the contracting, utilities, batching, energy, and transport sectors to address the rising regulatory and operational pressures associated with managing concrete wash water.

Regulatory Pressure Intensifies

Participants highlighted ongoing challenges around the current RPS 287 framework. While the regulatory position allows the storage and treatment of concrete wash water, it provides no clear or consistent disposal route. This lack of clarity has contributed to increasing bottlenecks, inconsistent site practices, and the perception that previous industry feedback had little influence on current guidance.

There was consensus that a clearer national direction is needed to ensure the safe, compliant, and practical management of wash water across various operational settings.

High-Risk Mismanagement Still Common

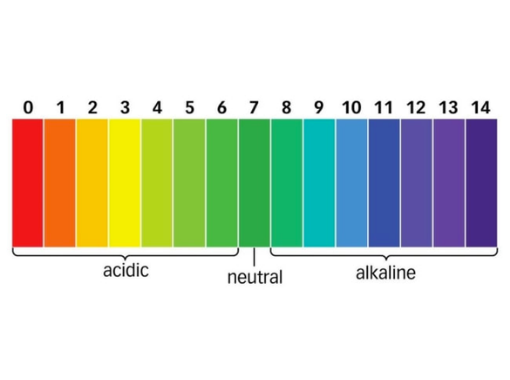

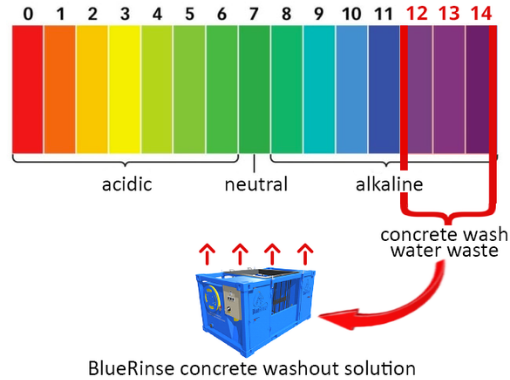

Real-world examples shared during the meeting demonstrated that high-pH wash water, typically in the range of 13 to 14, remains poorly managed on many sites. Instances were noted where hazardous loads were mislabelled, and skips were repeatedly used as makeshift containment solutions, allowing water to stay in prolonged contact with cement residues, further elevating pH.

Water utilities are increasingly taking a firm stance, with several significant fines issued for illegal sewer discharges. The threat of disconnection for sites that repeatedly breach consent limits is becoming more common, highlighting the urgency for better control and oversight.

Chromium (VI) Concerns Reassessed

The group also revisited long-standing assumptions regarding the presence of hexavalent chromium in concrete wash water. With modern cement formulations containing significantly reduced levels of Cr(VI) and no confirmed evidence of chromium transfer into wash water, participants questioned whether existing restrictions, especially those preventing reuse for dust suppression, remain justified. However, analytical detection challenges within commercial laboratories continue to complicate the issue.

Permitting Complexities Continue

Discussions provided clarity around permitting, confirming that surface water and groundwater discharges require the appropriate environmental permits, with specific exemptions possible for low-risk treated volumes. For sewer discharges, most water companies expect wash water to be neutralised to a pH of between 6 and 10, with solids removed and trade effluent consent in place.

Tankering, although widely used, was acknowledged as costly, carbon-intensive, and limited by the small number of facilities capable of accepting hazardous liquid waste.

Building Towards Best Practice

The Working Group agreed on a series of core principles that will serve as the basis for future industry guidance. These include minimising water use, quickly separating solids from liquids, treating wash water at source wherever possible, reusing treated water where safe, and avoiding unnecessary off-site transport.

Several attendees raised concerns over installed neutralisation and CO₂ systems that remain unused or poorly maintained. Improved training, oversight, and auditing were identified as essential steps towards raising standards across the sector.

Data Gathering and Next Steps

To strengthen the evidence base, members committed to supplying fresh wash water samples, monitoring results, detection capability information, and examples of successful exemption routes. A follow-up virtual meeting is scheduled for late November or early December, with an in-person workshop planned for February to agree on the direction of formalised industry guidance.