The British Concrete Transport Association (BCTA) has released a guidance document on the crucial issue of off-site disposal of concrete wash water. This comprehensive resource, available for download from the BCTA website, is a must-read for all industry professionals.

Concrete wash water produced through the washing or cleaning of any piece of plant or equipment is a waste material. BCTA stress that it should be appropriately treated in accordance with UK legislation relating to the storage, transport, and disposal of waste.

Mark Cowan, BCTA Advisor for Transport & Concrete, a key contributor to the guidance, underscores the importance of understanding the correct storage, transport, and disposal of concrete wash water. Mark, along with the expertise of his colleagues Mark Brooks and Jonathan Goldsmith, has provided information and awareness on hazardous, high pH water safety and environmental issues.

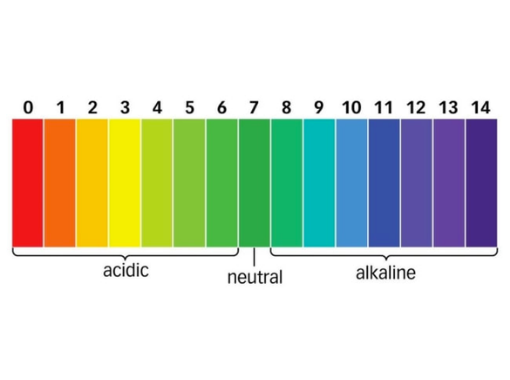

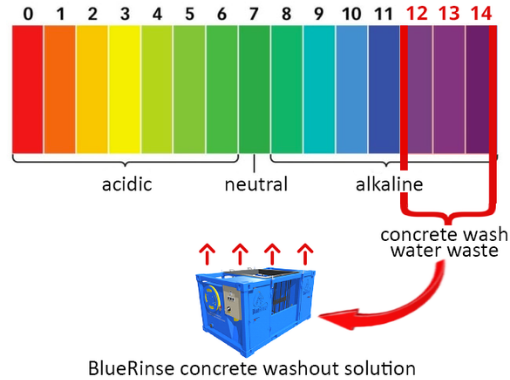

“It’s an area we’ve been trying to raise awareness on for several years and an issue that continues to confuse all sides of the industry. First and foremost, once the concrete wash water reaches 12.5 on the pH scale, it becomes ‘hazardous’, meaning it needs to be dealt with correctly, including assigning the correct code to describe the waste. The current use of the 17 01 01 European Waste Catalogue code should be replaced with 16 10 01*, as it needs to be described as a hazardous aqueous liquid, not concrete from construction or demolition activities.”

Often referred to as the Duty of Care for Waste Management, the white paper summarises the requirements and responsibilities of the waste producer in accordance with UK legislation.

Cowan continued: “Understanding the safety and environmental aspects of dealing with concrete wash water is essential. Everyone involved must make an effort to manage high-pH water effectively. This includes on-site management, driver interaction and understanding, and treatment when the water is returned to the concrete plant instead of passing the problem on to someone else. Industry guidance dating back ten years is outdated, so there is an urgent need to produce new guidance and standards and to raise awareness, which is what we’ve done through the BCTA.”

You can download your BCTA document copy here: https://britishconcrete.org/resources

If you’d like to learn more about the guidance or the BCTA, email info@britishconcrete.org or visit the website www.britishconcrete.org